Digital Twins Revolutionize Industrial Performance Management

The Virtual Revolution in Industrial Operations

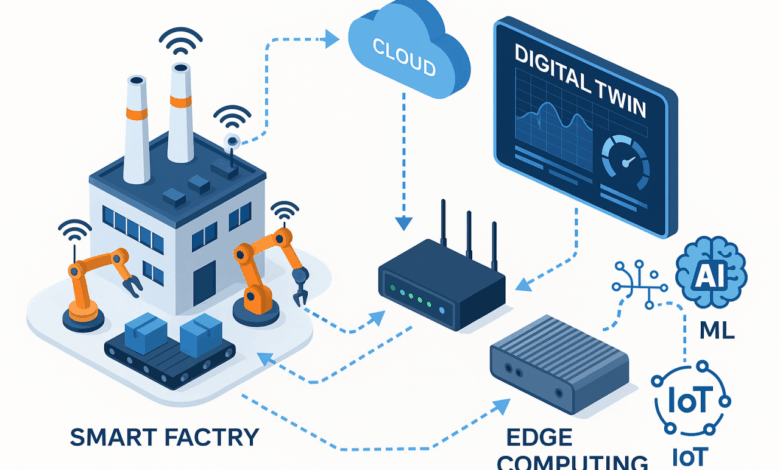

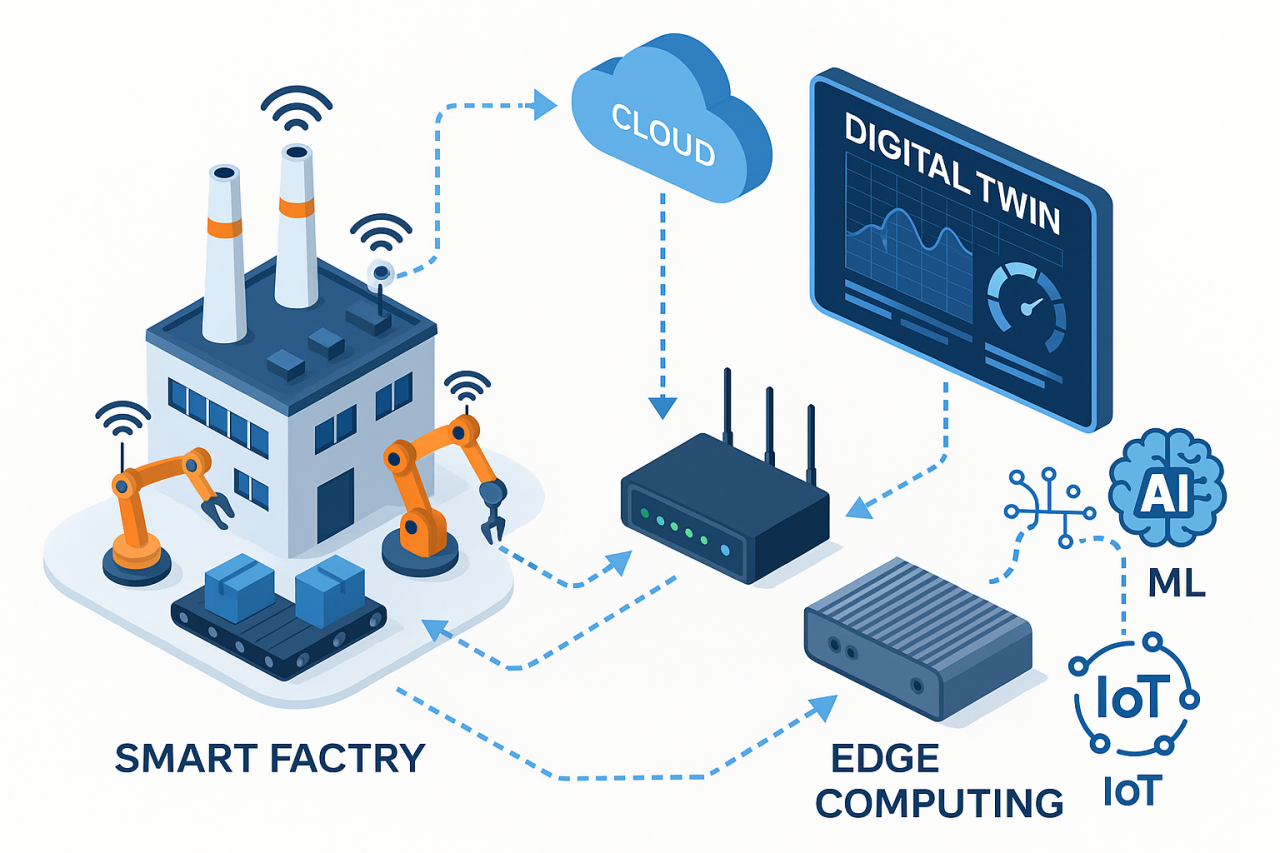

Digital twin technology has emerged as a transformative force in industrial operations, creating dynamic virtual replicas of physical assets, systems, and processes that enable unprecedented levels of optimization, prediction, and control. This technological paradigm represents far more than simple simulation—it involves the continuous, bidirectional flow of data between physical entities and their digital counterparts, creating living models that evolve in real-time. From manufacturing plants that anticipate equipment failures before they occur to supply chains that dynamically optimize themselves, digital twins are fundamentally reshaping how industries operate, maintain, and innovate. This comprehensive analysis explores how digital twin technology is transforming industrial operations, the underlying technologies enabling this revolution, implementation across various sectors, and the profound implications for efficiency, sustainability, and competitiveness in the global industrial landscape.

A. The Technological Foundation of Digital Twin Systems

Advanced digital twin implementations rely on multiple converging technologies working in harmony.

A.1. Data Acquisition and Sensor Technologies

Comprehensive data collection forms the foundation of accurate digital twins.

-

Industrial IoT Integration: Networks of sensors monitoring equipment performance, environmental conditions, and operational parameters in real-time, providing the raw data that powers digital twin accuracy.

-

Edge Computing Processing: Local data processing at the source enables immediate response to critical conditions while transmitting summarized data to central digital twin systems.

-

Wireless Sensor Networks: Advanced communication protocols that enable dense deployments of monitoring devices without complex wiring infrastructure, particularly valuable in existing industrial facilities.

A.2. Modeling and Simulation Capabilities

Sophisticated computational models create accurate virtual representations.

-

Physics-Based Modeling: Mathematical representations of physical processes, material properties, and mechanical behaviors that accurately predict how systems will perform under various conditions.

-

Data-Driven Model Enhancement: Machine learning algorithms that continuously improve model accuracy by comparing predictions with actual operational outcomes.

-

Multi-Scale Simulation: The ability to model systems at different levels of detail, from molecular interactions in materials to enterprise-wide operational dynamics.

A.3. Visualization and Interaction Interfaces

Advanced interfaces make digital twin insights accessible and actionable.

-

3D and Immersive Visualization: Detailed spatial representations that enable intuitive understanding of complex systems and relationships.

-

Augmented Reality Overlays: Digital information superimposed on physical views of equipment and facilities, blending virtual insights with physical reality.

-

Natural Language Interaction: The ability to query digital twins using conversational language, making sophisticated analysis accessible to non-technical users.

B. Implementation Across Industrial Sectors

Digital twin technology is delivering transformative results across diverse industrial domains.

B.1. Manufacturing and Smart Factories

Digital twins are revolutionizing production environments.

-

Production Line Optimization: Virtual models of entire manufacturing processes that identify bottlenecks, predict maintenance needs, and optimize throughput in real-time.

-

Quality Prediction and Control: Systems that anticipate quality issues before they occur by analyzing process parameters and environmental conditions.

-

Flexible Manufacturing Systems: Digital twins that enable rapid reconfiguration of production lines for different products while predicting impacts on efficiency and quality.

B.2. Energy and Utilities Infrastructure

Critical infrastructure benefits from digital twin predictive capabilities.

-

Predictive Maintenance for Power Generation: Detailed models of turbines, generators, and transformers that forecast maintenance needs based on actual operating conditions rather than fixed schedules.

-

Smart Grid Management: Virtual replicas of electrical distribution networks that optimize load balancing, predict outage risks, and integrate renewable energy sources efficiently.

-

Water Management Systems: Comprehensive models of water treatment and distribution systems that optimize chemical usage, energy consumption, and infrastructure planning.

B.3. Supply Chain and Logistics Operations

End-to-end visibility and optimization through digital twin technology.

-

Logistics Network Optimization: Virtual models of entire supply chains that simulate disruptions, optimize inventory levels, and identify efficiency opportunities.

-

Warehouse Operations Management: Digital twins of fulfillment centers that optimize layout, equipment utilization, and workforce allocation based on predicted order patterns.

-

Transportation Fleet Management: Comprehensive models of vehicle fleets that optimize routing, maintenance scheduling, and fuel efficiency while ensuring regulatory compliance.

C. Core Capabilities and Functional Benefits

Digital twins provide specific capabilities that deliver measurable operational improvements.

C.1. Predictive Analytics and Proactive Intervention

Anticipating issues before they impact operations.

-

Failure Prediction: Identifying equipment likely to fail within specific timeframes, enabling proactive maintenance that prevents unplanned downtime.

-

Performance Degradation Tracking: Monitoring gradual changes in equipment efficiency and effectiveness that might otherwise go unnoticed until causing significant problems.

-

Anomaly Detection: Automatically identifying unusual patterns in operational data that may indicate emerging issues or opportunities for improvement.

C.2. Optimization and Scenario Analysis

Testing improvements virtually before implementing them physically.

-

What-If Analysis: Evaluating the potential impact of operational changes, new equipment, or modified processes without disrupting actual operations.

-

Constraint Optimization: Identifying optimal operating parameters within complex sets of physical, regulatory, and business constraints.

-

Resource Allocation Optimization: Dynamically allocating personnel, materials, and equipment to maximize overall operational efficiency.

C.3. Training and Skills Development

Using digital twins as safe, effective training environments.

-

Operator Training Simulators: Realistic virtual environments where personnel can develop skills without risk to equipment or personal safety.

-

Emergency Response Preparation: Simulating rare but critical failure scenarios to ensure personnel are prepared to respond effectively.

-

Procedural Validation: Testing and refining standard operating procedures in virtual environments before implementation.

D. Implementation Challenges and Strategic Approaches

Successful digital twin deployment requires addressing significant technical and organizational challenges.

D.1. Data Management and Integration Complexity

Creating accurate digital twins requires comprehensive, high-quality data.

-

Legacy System Integration: Incorporating data from older equipment and systems not designed for modern data extraction and connectivity.

-

Data Quality Assurance: Establishing processes to ensure the accuracy, completeness, and timeliness of data feeding digital twin systems.

-

Cross-System Data Harmonization: Integrating information from disparate systems with different data models, formats, and update frequencies.

D.2. Organizational and Cultural Considerations

Technology implementation must address human factors.

-

Workforce Adaptation: Helping employees transition from traditional operational approaches to data-driven decision-making supported by digital twins.

-

Cross-Functional Collaboration: Breaking down organizational silos to create digital twins that span traditional departmental boundaries.

-

Skills Development: Building the technical and analytical capabilities needed to develop, maintain, and leverage digital twin systems effectively.

D.3. Technical Infrastructure and Security

Robust infrastructure is essential for digital twin success.

-

Computational Resource Requirements: Providing sufficient processing power for complex simulations without excessive latency.

-

Cybersecurity Protection: Securing digital twin systems against unauthorized access, manipulation, or disruption.

-

System Reliability: Ensuring digital twin availability matches the criticality of the operations they support.

E. Technology Enablers and Ecosystem Development

Advanced technologies are making increasingly sophisticated digital twins possible.

E.1. Artificial Intelligence and Machine Learning

AI dramatically enhances digital twin capabilities.

-

Automated Model Calibration: Machine learning systems that continuously adjust digital twin parameters to maintain alignment with physical counterparts.

-

Pattern Recognition: Identifying complex relationships in operational data that would be difficult for humans to detect.

-

Natural Language Processing: Enabling interaction with digital twins using conversational language rather than technical interfaces.

E.2. Cloud and Edge Computing Infrastructure

Modern computing architectures enable practical digital twin deployment.

-

Cloud Scalability: The ability to access virtually unlimited computational resources for complex simulations and analyses.

-

Edge Processing: Local computation that enables immediate response to time-critical conditions while leveraging cloud resources for deeper analysis.

-

Distributed Digital Twins: Systems composed of multiple interconnected digital twins representing different aspects of complex operations.

E.3. Advanced Visualization and Interaction Technologies

Making digital twin insights accessible and actionable.

-

Virtual Reality Immersion: Fully immersive experiences that enable intuitive understanding of complex systems and relationships.

-

Augmented Reality Overlays: Superimposing digital twin information on physical views of equipment and facilities.

-

Collaborative Visualization: Systems that enable multiple users to interact with and discuss digital twin visualizations simultaneously.

F. Future Directions and Emerging Applications

Digital twin technology continues to evolve with expanding capabilities and applications.

F.1. Autonomous System Integration

Digital twins as essential components of autonomous operations.

-

Closed-Loop Control Systems: Digital twins that not only monitor and predict but automatically implement optimizations through connected control systems.

-

Autonomous Decision Validation: Using digital twins to verify that autonomous systems are making appropriate decisions before implementation.

-

Self-Healing Systems: Infrastructure that uses digital twins to detect and correct issues without human intervention.

F.2. Sustainability and Environmental Applications

Leveraging digital twins for environmental benefits.

-

Carbon Footprint Optimization: Models that identify opportunities to reduce energy consumption and greenhouse gas emissions.

-

Circular Economy Enablement: Tracking materials throughout their lifecycle to facilitate reuse, remanufacturing, and recycling.

-

Environmental Impact Modeling: Predicting and minimizing the environmental consequences of industrial operations.

F.3. Enterprise-Wide Digital Twin Ecosystems

Expanding digital twins beyond individual assets to entire organizations.

-

Organizational Digital Twins: Comprehensive models that include physical assets, business processes, and human resources.

-

Supply Chain Digital Twins: End-to-end models spanning multiple organizations and geographical regions.

-

Digital Twin Marketplaces: Platforms for sharing and trading validated digital twin models of common equipment and systems.

Conclusion: The Virtual Transformation of Industrial Operations

Digital twin technology represents a fundamental shift in how industrial operations are managed, optimized, and evolved. By creating dynamic virtual counterparts to physical assets and processes, organizations gain unprecedented visibility, predictive capability, and control over their operations. The most successful implementations demonstrate that digital twins are not merely technological tools but foundational elements of modern industrial strategy—enabling continuous improvement, risk reduction, and innovation at a pace and scale previously unimaginable. As digital twin technology continues to mature and become more accessible, it will inevitably transition from competitive advantage to operational necessity across virtually all industrial sectors. In this context, organizations that master digital twin implementation will be positioned to lead their industries in efficiency, sustainability, and resilience—transforming not only their own operations but potentially reshaping entire industrial ecosystems. The virtual revolution in industrial operations is well underway, and digital twins are at its forefront, creating a future where every significant physical asset has a digital counterpart working tirelessly to optimize its performance and extend its productive life.

Tags: digital twins, industrial transformation, smart manufacturing, predictive maintenance, IoT technology, industrial automation, virtual simulation, operational optimization, Industry 4.0, digital transformation, asset performance, smart operations